Vertical Roller Mills – LNV TECHNOLOGY

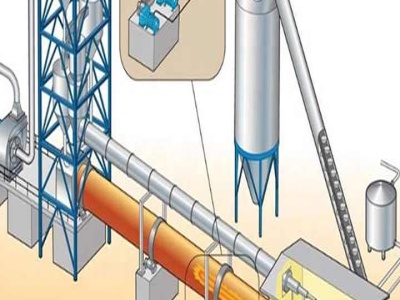

Vertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is .