mechanical maintenance department of thermal power plant ...

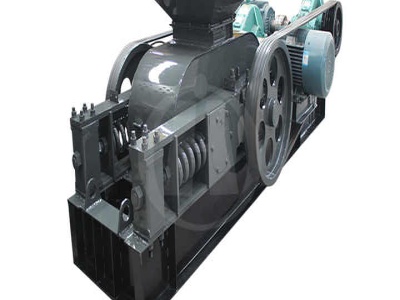

Coal mill pulverizer in thermal power plants SlideShare. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill.