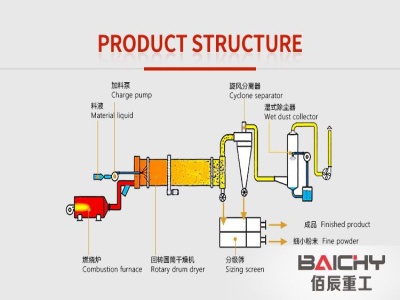

flow diagram process of grate kiln iron ore pellet plant

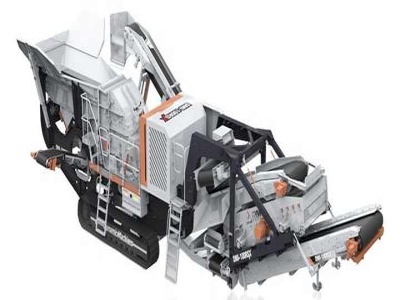

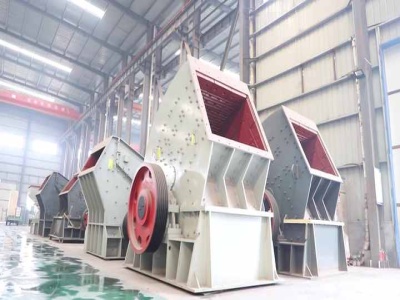

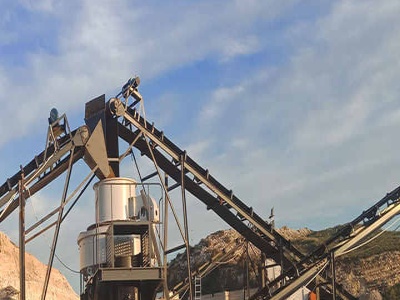

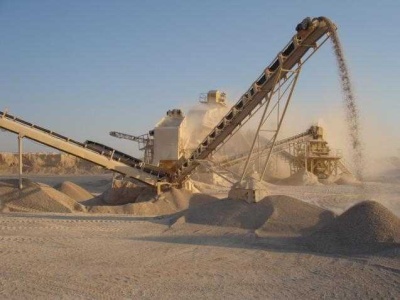

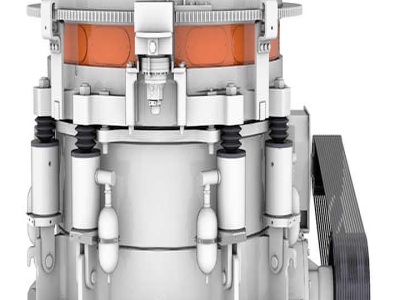

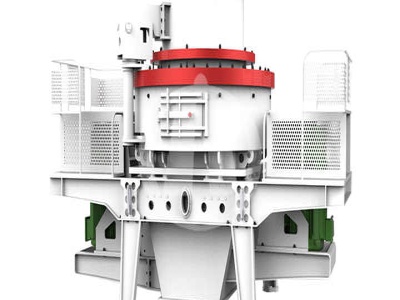

iron ore pellet plants flow chart . iron ore crushing plant flow chart . iron ore crushing and screening plant flow chart. screening iron ore pellets Mining equipment mine process iron ore fines grinding bangalore india Mobile crusher for sale Iron ore crushing and screening. /10() flow chart of 1000 tph iron ore crushing plant Logitech Finally Made a Keyboard Worthy of ...