What is Dispersion Equipment | Custom Milling Consulting ...

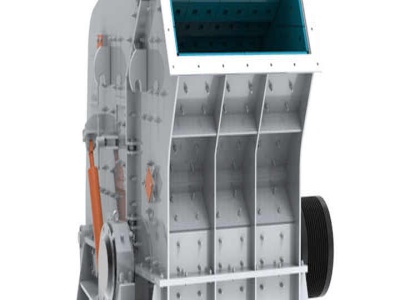

The goal is also to achieve very fine particles, so that there is a higher and even dispersion with in the liquid. Custom Milling Consulting, Inc. builds customized milling equipment that processes wet materials that range in viscosity. They specialize in particles size reduction and dispersion technology. Equipment: Horizontal Media Mill