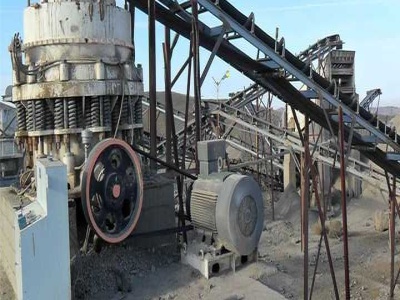

Cement: Materials and manufacturing process

• Chemically, cement is a mixture of calcium silicates and small amounts of calcium aluminates that react with water and cause the cement to set. • Calcium derives from limestone and clay, mudstone or shale as the source of the silica and alumina.