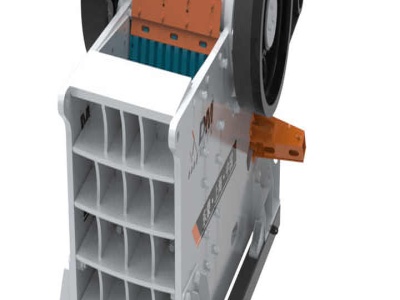

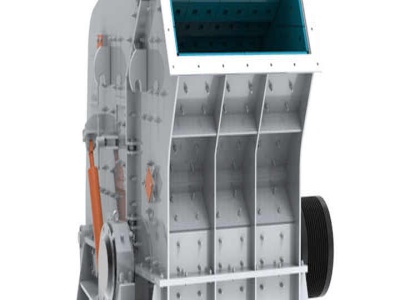

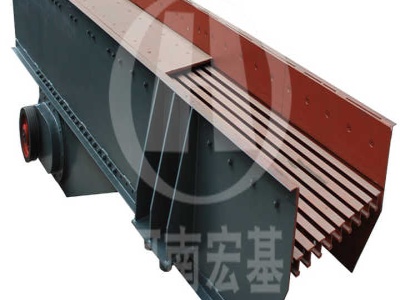

upgrade on a crusher at a mine BINQ Mining

Feb 10, 2013· Process Of Upgrading Iron Ore Concentrates | Manganese Crusher. Zenith Mining and Construction Machinery is a global . ore beneficiation plant to upgrade iron ore by increasing the iron . used bucket excavator crusher; »More detailed