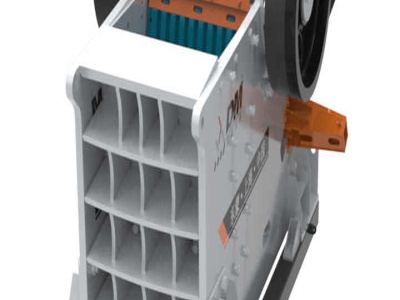

primary stone crusher working principle

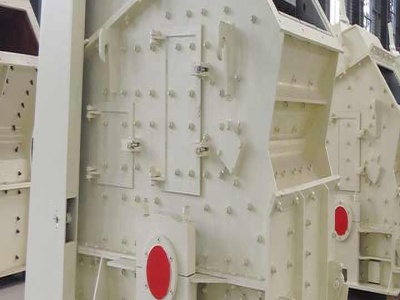

Generally, stone crusher can be divided into: jaw crusher, impact crusher and cone crusher. These crushers have different working principles. These crushers have different working principles. Jaw crusher: When the rock crushing machine works, motor drives belt and pulley, and the eccentric shaft drives the mobile jaw plate.