REMOVAL OF SULFUR AND PHOSPHOROUS FROM IRON ORE ...

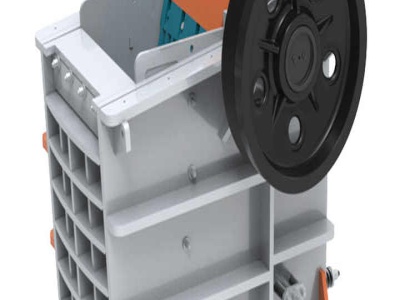

sulfur content was removed from the iron ore concentrate by the chemical leaching. Effects of several parameters, including temperature, stirring speed, particle size, and use of organic solvent on the sulfur