Development of Millburner System for Lowrank Coal with ...

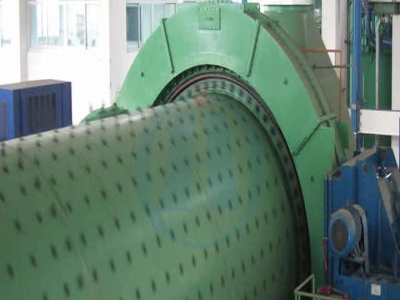

|3. Grinding and drying test with vertical roller mill For the study of the grindability and drying characteristics of highmoisture coal with the vertical roller mills, grinding and drying tests were carried out using a reducedscale model of a vertical roller mill to verify the continuous and stable operation and drying characteristics.