Basic Types of Drilling Machines

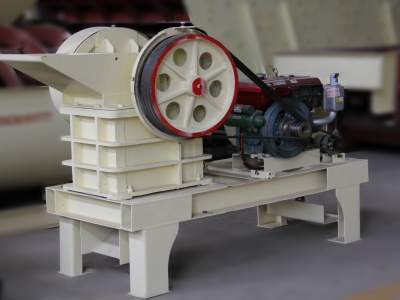

The upright sensitive drill press (Figure 1) is a lightduty type of drilling machine that normally incorporates a belt drive spindle head. This machine is generally used for moderatetolight duty work. The upright sensitive drill press gets its name due to the fact that the machine can only be hand fed.