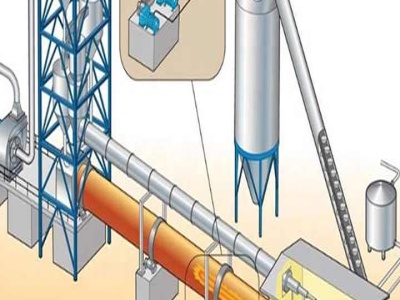

What is Pilgering Pilger Mill Technologies

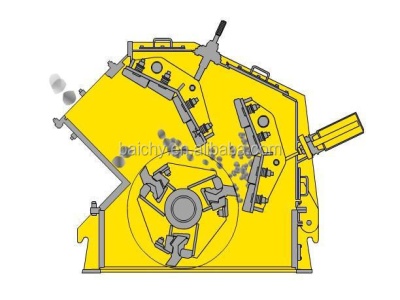

In general, the pilgering process has two primary purposes: *One, and most importantly, pilgering is a cold working process that greatly improves the material grain structure. *Two, it is a way of reducing large amounts of the outside diameter and inside diameter of a preexisting tube very quickly.