Rail Grinding Best Practice

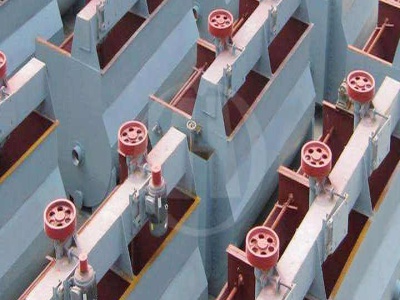

the grinding stones, the forward speed of the machine and the hardness of the rail surface being worked on. Production Rail Grinding The grinding of long sections of curved and tangent (straight) track on a tonnage or time based frequency. Spot Grinding and Switch and Crossing Grinding