Mill dictionary definition | mill defined

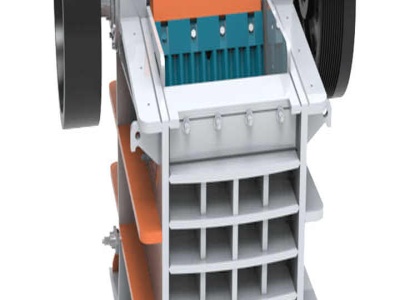

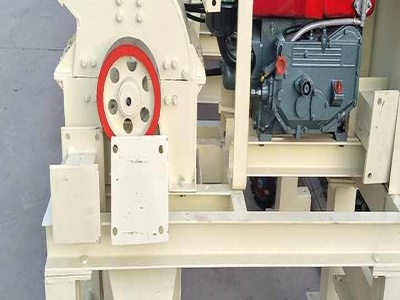

mill definition: The definition of a mill is a machine that grinds solid materials into smaller pieces. (noun) An example of a mill is a place where flour is made by grinding grain....