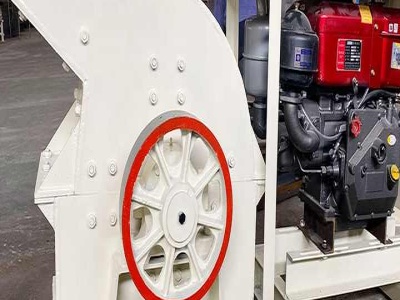

The ball mill discharges "running rough", and the fineness ...

the grinding volume of the coarse grinding bin is too small, the diameter of the steel ball is too small, or the filling rate of the grinding body of the fine grinding bin is too low, the loading amount of the grinding body should be increased, and the grading of the grinding body should be adjusted to increase the size.