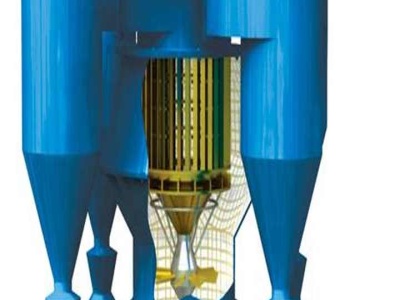

Dry slag granulation with integrated heat recovery

Dry slag granulation could make a fundamental change in slag treatment. In this new approach, molten slag is atomized under centrifugal forces on a spinning disc, and the droplets generated are quenched and solidified quickly using air, with simultaneous heat recovery.