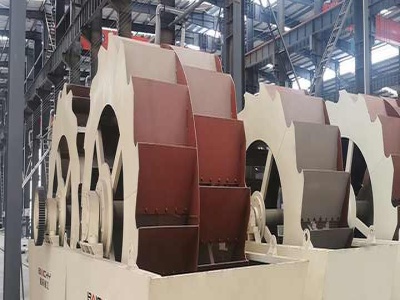

flow sheet of cement production

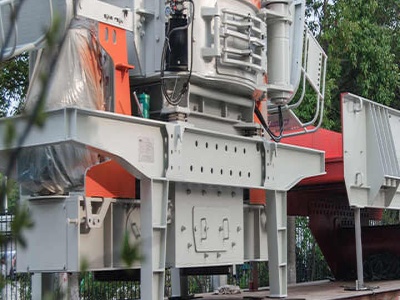

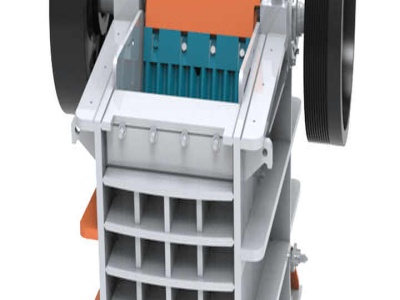

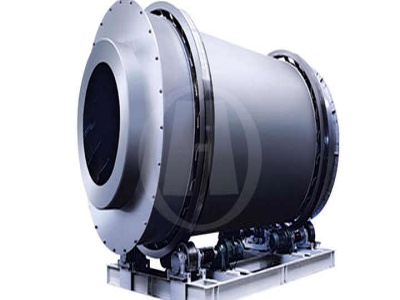

flow sheet of cement production manufacturer in Shanghai, China. flow sheet of cement production is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions.. SKD stone crushing machine projectflow sheet of cement production. cement production process with flow sheets cement production process with flow sheets.