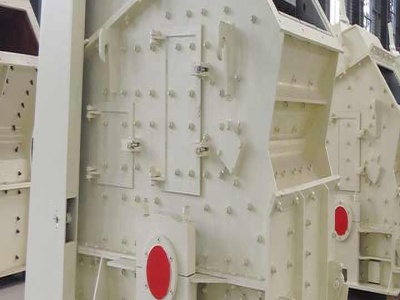

Grinding Systems Hammer Mill Manufacturer from Thane

Air swept Mill is a screenless pulverizer suitable for grinding of soft as well as hard and brittle materials like minerals, gum, turmeric, ginger, sugar etc. to a fineness of 100 to 300 Mesh BSS.