gravity separation of concentration of ores Products ...

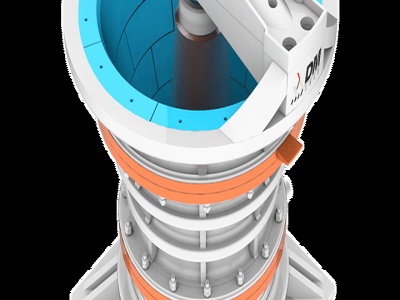

[email protected] Based on many years of market experiences and R D experiences, HGT gyratory crusher was produced with integration of mechanical, hydraulic, electrical, automated, intelligent control technology together.