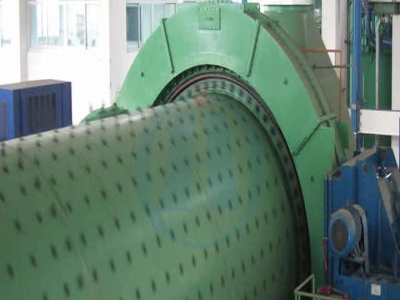

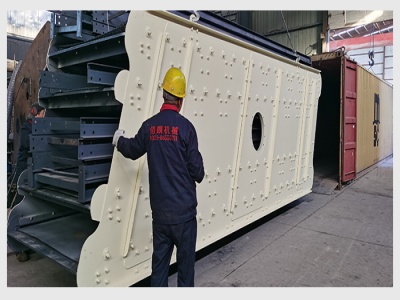

Cement Extraction and processing |

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

![crushing at cement plant[mining plant]](/vyh0c3w/512.jpg)

![crushing at cement plant[mining plant]](/vyh0c3w/871.jpg)