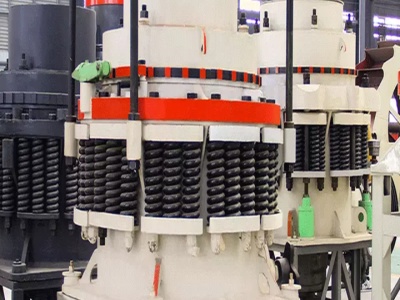

Cone crusher basic movement

Apparatus For Measuring The Gap Width In A Cone Cr . he cone crusher is subject to high wear and tear because of the crushing cone crusher mantle to the running tumbling like flapping movements, exerted by the hammerlike blows without interruption on a on a circular zone falling down crushed material The gap width between the crusher and cone crusher mantle changed due to wear