Lucky Cement is one of the Leading Exporters of cement in ...

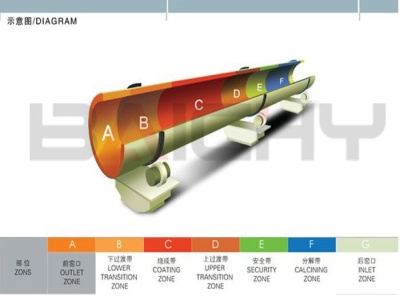

Lucky Cement greatly emphasizes in manufacturing high quality product through stringent quality control techniques and computerized control systems. Quality of the cement has been tested and proven up to the specifications mentioned in Pakistan, British, Indian, Kenyan, Nigerian, South African and .