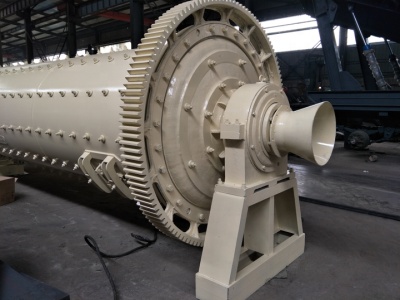

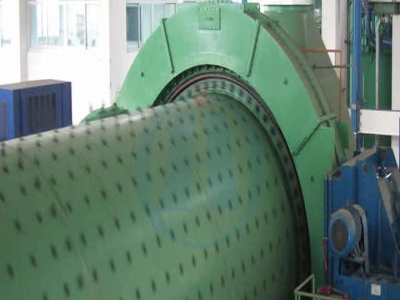

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: .

raw meal, while in the current work an attempt is made to regulate the cement mill operation in an optimal way; (ii) the simulation of the raw meal mixing process included the uncertainties of the raw materials, while in this study the uncertainty of the dynamical parameters is directly incorporated in .