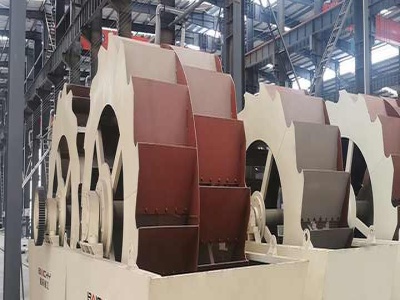

3 rollers vertical coal mill in cement plant

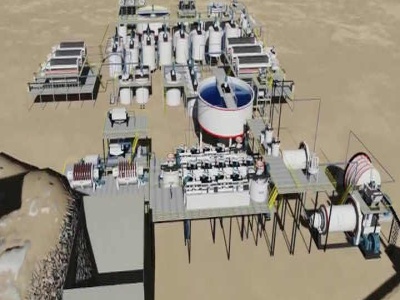

Loesche has now sold four mills comprising one raw mill, one coal mill and two clinker mills to Pakistan. Bestway Cement Company want to use these to modernise their Farooqia cement plant in the Punjab province, 40 km north of the capital, Rawalpindi. One highperformance 4roller mill VRM with a capacity of 450 t/h is to be used there for the ...