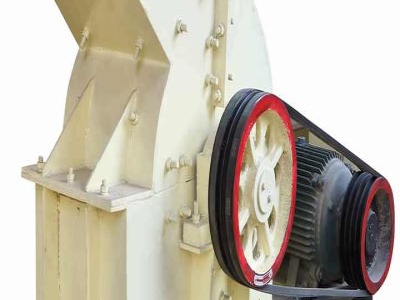

Primary Crusher Base Reinforced with Belzona Concrete ...

May 13, 2019· A primary crusher is a great example of a machinery subject to the effects of harsh environment. In a past blog, Mining Quarrying: Belzona's Top 5 Application Areas, we highlighted the common issues associated within the mining industry.