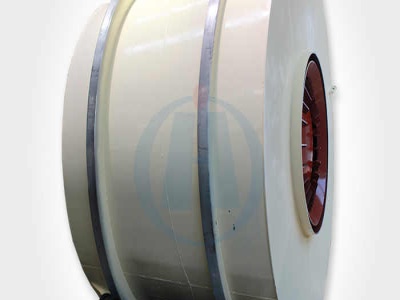

GRINDING WHEEL and ABRASIVES BASICS

Grinding wheels usually will be between 24 and 100 grit. Honing stones and jointing stones and other polishing abrasives will be 150 grit and higher. Use a coarse grit for fast, aggressive stock removal and finer grits for less stock removal but better surface finish. Grinding wheel hardness