Magnetic Separation Principles and Application in ...

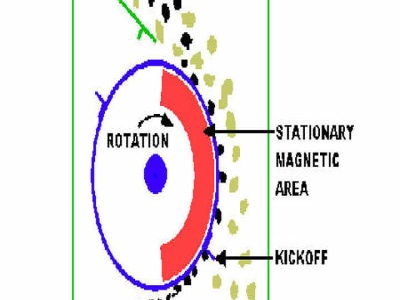

Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body. The magnetic fraction may be valuable or gangue depending upon its end use in a particular process and so also the nonmagnetic fraction,, separation of magnetite (magnetic) from quartz (nonmagnetic), separation of tin ...