Vertimill VS Ball Mill Grinding Classification ...

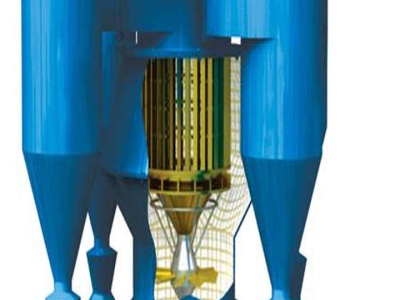

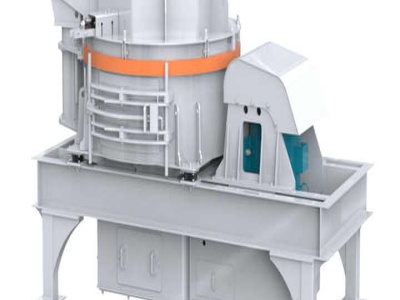

I see that several have answered based on dry grinding, Vertical Roller Mill vs. conventional Ball Mill. If we instead focus on wet grinding, we should differentiate between stirred media grinding, which can be both vertical and horizontal, and tumbling mills with manufactured grinding bodies.