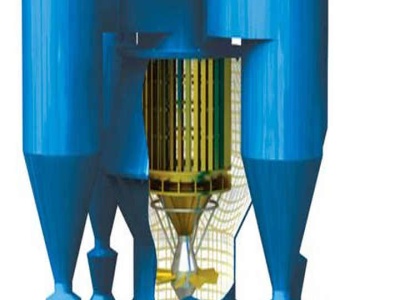

Iron Ore Magnetic Separation Process View Magnetic

Iron Ore Magnetic Separation Process View Magnetic. Magnetite ore Fe3O4 is a ferromagnetic mineral commonly used in magnetic separation coal washing processes Coal washing using magnetite is used to remove contamination from runofmine ROM coal which usually contains rocks middlings used consumables and other contamination introduced by the mining process.