Application of magnetic separation technology for the ...

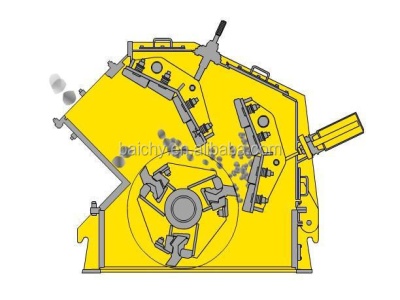

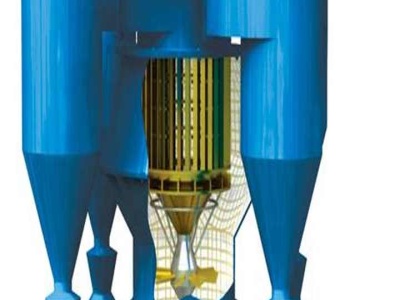

fraction by magnetic separation. Magnetic separation of the crushed and sized ore samples (5 mm +75 µm) was performed using a high intensity permanent magnetic separator. Under the test conditions a colemanite concentrate ( wt.% B2O3) was found to be produced from the crushed ore ( wt.% B2O3) at a recovery of %.