INTERNATIONAL JOURNAL OF SCIENTIFIC TECHNOLOGY .

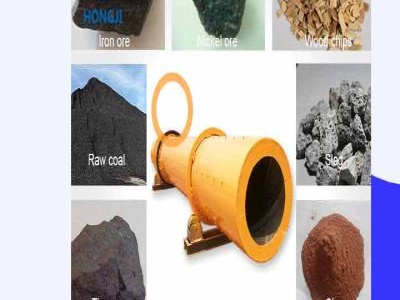

(respectively); P is the efficiency of blast furnace per unit time; δ is the unit quantity (at 1t. of cast Iron) of gasified oxygen. p. 2. Blast Furnace Peripheral Zone. Other things being equal, the utilization of CO depends on the amount of time the furnace charge remains in the indirect reduction zone.