NiHard

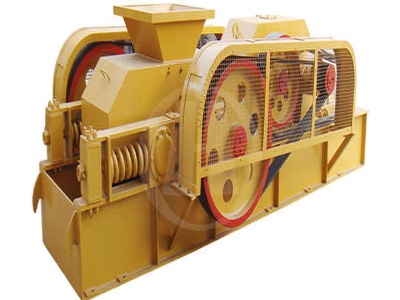

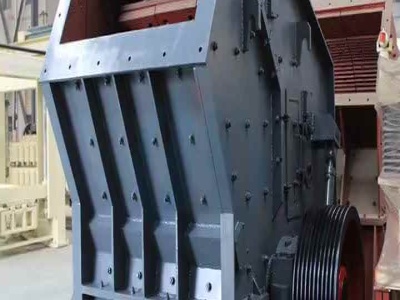

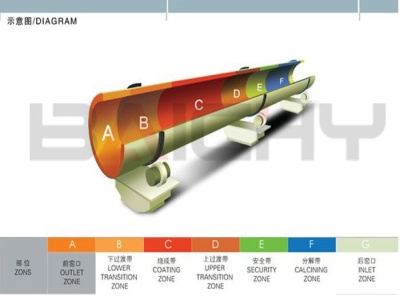

cement, ceramic, paint, dredging, coalcoke, steel and foundry industries. As grinding balls, mill liners, pulverizer rings and roll heads, slurry pump parts, pipes and elbows, wearbacks and metalworking rolls– the range of properties inherent in the different grades of NiHard has made it a worldwide success.