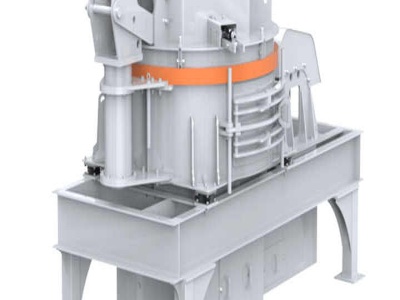

GRINDING MILLSBALL MILLSNew Used Mining Mineral ...

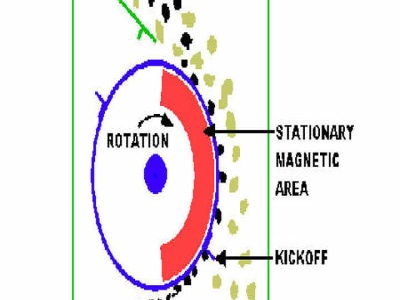

A ball mill is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are .