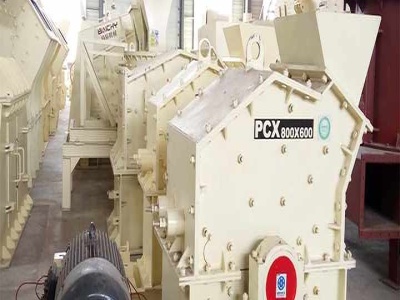

Shaft kiln utilized for lime production PREDESCU; LUCIAN A.

May 31, 1988· A vertical shaft kiln utilized in calcining limestone defines a series of processing zones including an upper preheating zone, a first calcining zone, a second calcining zone having a length twice that of the first calcining zone and a material cooling zone, Burners inject burnt gases intermediate the two calcining zones.