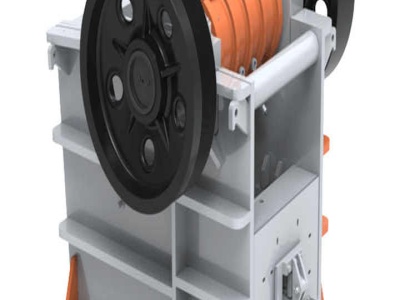

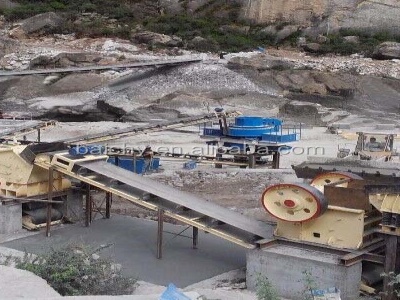

beneficiation and pelletization of iron ore

Apr 12, 2019· Iron ore mining often focuses on looking for hematite deposits known as red iron ore, and magnetite, as they have naturally weak magnetic fields that aid in their purification. Hematite, however, responds better to the flotation process in iron ore beneficiation than magnetite, so .