Iron Ore Mineral Technologies

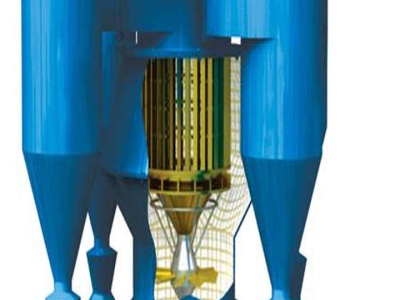

Innovative Plant Design. Having developed an effective and optimised flowsheet, you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst delivering high availability, with low capital and low operational expenditure. Our teams understand these challenges and bring a depth...