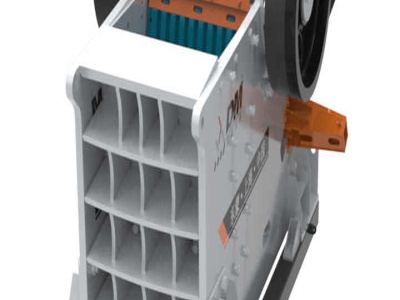

Vertical Coal Mill Great Wall

Great wall Machinery Vertical Coal Mill with advanced grinding mode, so that energy consumption is reduced by 30%~40% compared with that of ball mill. Due to its unique sealing structure design, the whole system is under negative pressure, so there is no dust in the production process, noise.