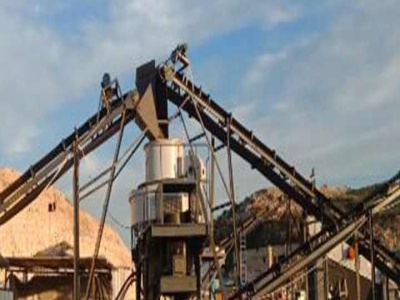

mining process mills

Pelletizing mills Mining, mineral processing and cement. Processes. ... Horizontal grinding mills. Flotation cells. Pelletizing mills. Pelletizing mills Challenging conditions. Mixing iron ore with a binder, then passing the material through a balling mill to produce pellets takes a heavy toll on the machinery and components involved.