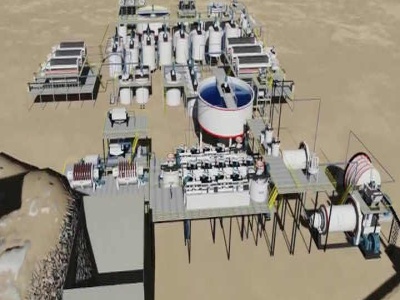

Mining with Trucks vs Belt Conveyors

Sep 16, 2013· Mining with Trucks vs Belt Conveyors ... Appreciate that the equipment cost for a long conveyor is dwarfed by the route/road preparation cost of either a conveyor or trucking option. Road maintenance is less for a conveyor. ... The study of many overland conveyor (OLC) vs. truck haulage reveal some basic and new facts: 1. Break even point for ...