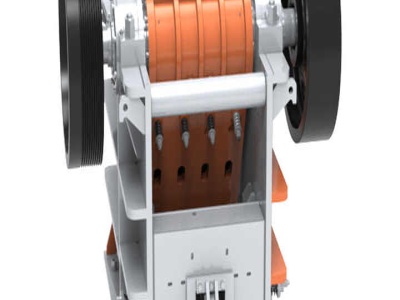

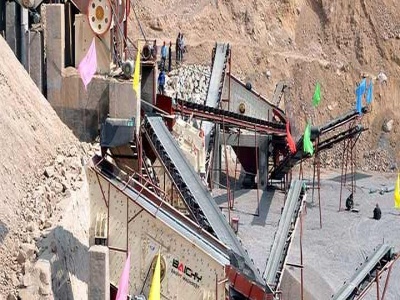

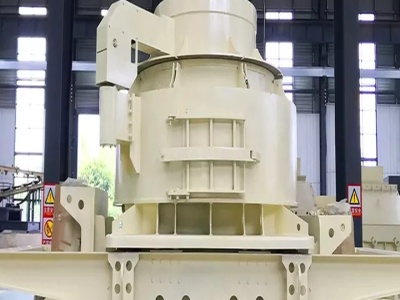

Copper Mining and Processing: Processing of Copper Ores ...

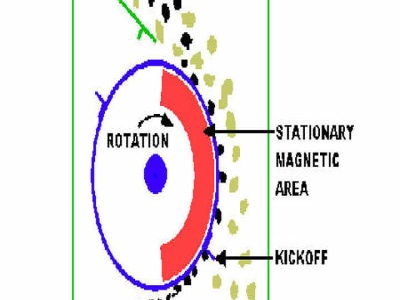

After the copper ore is crushed, liquid is added to make it a slurry. The slurry is a mix of valuable copper ore minerals and "worthless" rock, called gangue (pronounced "gang"). The slurry is placed in a tank and a process called froth floatation is used to separate the copper minerals from the gangue.