SLR Environmental Consulting (Namibia) (Pty) Ltd Page vi

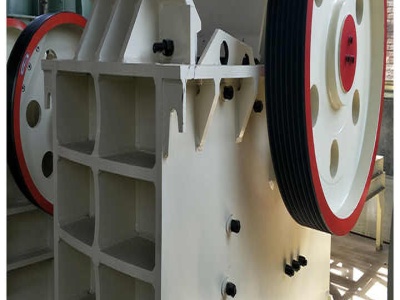

• Upgrading of the slag mill to improve copper recovery and handle the increased tonnage from ... • Slag slow cooling in pots or pits before crushing by an independent contractor; ... o Rationalization of flotation capacity by elimination of oxide rougher bank #2 and oxide cleaner