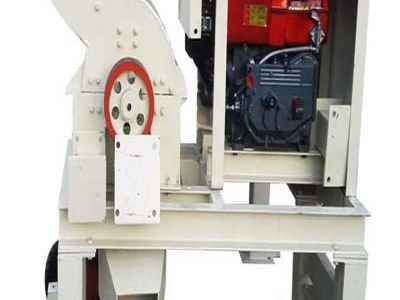

Manual Mill Basics 201

Objectives. Describe the basic function and operation of the manual mill. Describe manual milling machine types. Identify machine components of the vertical column and knee mill. Describe common cutting operations performed on the mill. Describe various cutting tools used on the mill. Describe common toolholders used on the mill.