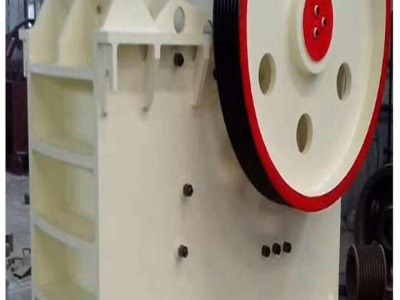

JoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher ...

The JOYAL Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa.