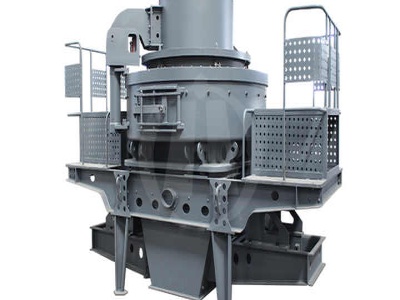

LUM Ultrafine Vertical Mill

The optimized roller, millstone and inner airflow guidance design greatly improve the grinding efficiency. The capacity of LUM ultrafine vertical grinding mill is 30% higher than similar products and the power consumption is 30%60% lower than ball mill. 3. Intelligent control system makes operation more stable and .