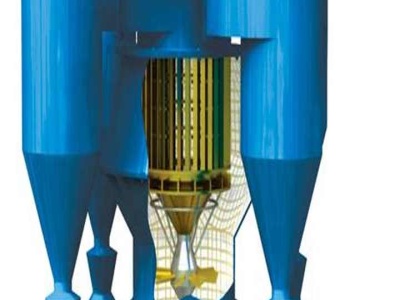

hemitite floatation

floatation process hematite jessikaateliernl ore flotation separation process the best results hematite flotation s Processes for phosphorus removal from iron ore a Mineral Processing Flotation Magnetite And Factors Affecting the Hematite Flotation Effect Xinhai The hematite itself has a magnetic, so the hematite beneficiation process using gravity separation, magnetic separation and .